Ultrafast Lasers

Micromachined Films

FAMous-Drilling Machine

Flexible panel processing

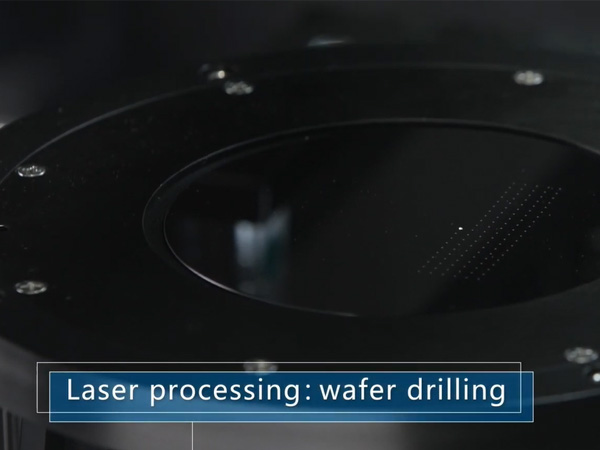

FAMous is designed to provide micromachined films fabrication with an excellent quality and a high throughput, which can be applied to the solution of the flexible panel processing. According to customers' requests, generally, the machining quality, including the cutting width, crater, burr and HAZ, will be the dominant factor for the product processings.

Furthermore, the takt time is definitely a crucial criterion for a laser processing machine.

Laser Drilling Features

Round, square and other hole shapes capability

Hole taper control (positive, negative and zero taper)

Precise control of hole depth ≤ 5 μm

Smooth inner wall (Ra ≤ 1 μm)

Possible Machined Materials

Polyimide (PI)

Polyester (PET)

Metal Foil

Organic Film

Polymethyl Methacrylate (PMMA)

Liquid Crystal Polymer (LCP)

Glass-reinforced laminates (e.g. FR-4, BT, RT Duroid)

Coverlay (Polyimide + Adhesive)

Copper-clad polyimide laminates with adhesive

Any material with thickness smaller than 0.5 mm is also possible

Performances

| Model | 1-D Ablation for Cutting |

|---|---|

| Takt Time | > 300 mm/s |

| Thickness | < 100 μm |

| Line Width | < 10 μm |

| Crater Height | < 1 μm |

| HAZ | < 10 μm |

| Model | 2-D Ablation for Laser Lift-Off (LLO) |

| Takt Time | >600 mm2/s |

| Thickness | PI |

| Line Width | glass, sapphire, etc |

| Crater Height | < 1 μm |

| HAZ | PI with a high transmittance after LLO |

| Model | 2-D Ablation for Other Applications |

| Takt Time | >1 mm3/s |

| Thickness | < 10 μm |

| Line Width | < 1 degree |

| Crater Height | < 1 μm |

| HAZ | < 50 μm |

Need Inquire ?

If you need more information or quotation about this product, Our sales representative will reply as soon as possible